High definition Flexo Printing Machine - Syk1224 4 Color Printing Slotting Die Cutting With Stacking Machine – Xinguang

High definition Flexo Printing Machine - Syk1224 4 Color Printing Slotting Die Cutting With Stacking Machine – Xinguang Detail:

|

MANE |

Model specifications |

Quantity |

|

Paper feed unit |

SYK1200x2600 |

1set |

|

Printing unit |

SYK1200x2600 |

4set |

|

Slotting unit |

SYK1200x2600 |

1set |

|

Die cutting unit |

SYK1200x2600 |

1set |

|

stacking unit |

SYK1200x2600 |

1set |

Machine Feature:

The main electric elements all adapt famous brand. PLC controlling, colorful touch screen , frequency converter.

The transmission gear adopt 40 Cr, 20GrMo Ti high quality alloy steel which is grinded, and after the heat treatment ,it can up to six grade precision.

The machine lubrication system uses an automatic spray lubrication, and with the device impermeable to oil spills institutions.

Each unit of the machine with electric separation, and pneumatic locking, pneumatic total lock, to ensure the stability of the unit, and continue ring for caution when machine be separated, to ensure the safety of operating person.

Every unit of machine with emergency stop switch, so the machine can be stopped between the unit, it can ensure the workers safe (remark: every unit moving is drag by feeder unit)

Main parameter

|

Type |

Unit |

SYK1200x2600 |

|

Inner width of machine |

mm |

2800 |

|

Speed |

pcs/min |

200 |

|

Max printing area |

mm |

1200×2400 |

|

Max feeding paper size |

mm |

1270×2600 |

|

Feeding paper by skip |

mm |

1400×2400 |

|

Min feeding paper size |

mm |

320×640 |

|

Topping precision |

mm |

±0.5 |

Printing department:

1) Printing of high quality thick-walled seamless steel roll, surface conditioning, grinding, hard chromium plating.

2) All axes of roller correct by dynamic balance, the machinery running steady.

3) Handling print, the foot switch is convenient and flexible electric control reversing.

4) Printing , roller clearance adjusted by hand, the scale panel shows the data.

5) Printing phase fixed device, using pneumatic brake mechanism. While the machine separates or the phase is adjusting, the brakes can restrict the revolving of the machine platform and keep the fixed point of original gears position.

Rubber roller: the surface of the roller is steel pipe which is packed by the wear-resisting rubber. Adopting medium and high special grinding the rubber roller has effective ink-spreading.

The steel roller adopt high precision hard chrome plating net-grain roller.

Installed with ink roller rotation electrical machinery to avoid the main engine’s drying up while its stopping.

Slotting department:

The function of the double shaft slotting unit (adopt units). Big size carton box or kicking paperboard slotting can save loading knife time.

Slotting phase and the height carton box adjusting, computer and the electrical number can be controlled.

Slotting knife with a move transversely structure, screw with linear axis that mobile more flexible and accurate.

The up and down knife move at the same time, keep the linkage of knives, accurate, extend the service life tools.

Slotting knife shaft space, computers and digital electronic adjustment automatically.

The slotting knife move transversely with double prevent collision protection device (electronic and mechanical).

Elastic and corner cutting blade structure, three and five layers board corner cutting no adjustment and operation more convenient.

Line wheel, slotting knife move transversely adjustment, electric control.

Creasing gap adjusting with computer and digital electronic control (choose configuration).

Diecutting department:

1 knife die roll (lower roll)

The outer diameter is ¢360㎜

Balance correction, increase operation stability.

Applicable to die height of 22.5 mm.

Rubber cushion roller (upper roller)

The outer diameter is ¢388.9㎜.

Cast iron surface grinding, hard chromium plating.

Balance correction, increase operation stability.

Manual adjustment of clearance with die roll.

The thickness of the pad is 8 mm and the width is 125 mm

Mechanical transverse 40-inch swimming device.

3.Phase adjusting mechanism

1.Planetary Gear Structure.

2.The phase of die-cutting is adjusted by LCD micro-computer Electric-Digital 360 degree. (Adjustable operation and stopping)

3.Manually adjust the lateral position, adjust the distance to a total of 20 mm.

Detailed list of motor and important parts:

|

Name |

Place of origin |

Specifications |

Number |

|

Paper feed Department |

Tianjin |

||

|

1. Main motor |

Hengshui, Hebei |

Variable frequency motor18 |

1 |

|

2.Machine opening and closing |

Hebei |

0.75KW 59/1 Gear motor |

1 |

|

3.Adsorption fan |

Gaobeidian |

7.5KWCentrifugal fan |

1 |

|

4.Adjustment of rear gear box |

Zhejiang

|

0.18KW 1/25 Gear motor |

1 |

|

5.Dust removal fan |

Baoding |

2.2KW |

1 |

|

Printing Department |

|||

|

1.Phase adjustment |

Zhejiang |

0.37KW 15/1 Gear motor |

1/color |

|

2.rubber roller idling |

Shanghai motor |

0.75KW 43/1 Gear motor |

1/color |

|

Slotting Department |

|||

|

1.Phase adjustment |

Zhejiang |

0.37KW 15/1 Gear motor |

1 |

|

2.Transverse movement of cutter head |

Zhejiang |

0.37KW 40/1 Gear motor |

4 |

|

3.Adjustment of carton height |

Zhejiang |

0.37KW 1/40 Gear motor |

1 |

|

Die cutting Department |

|||

|

1.Phase adjustment |

Zhejiang |

0.37KW 15/1 Gear motor |

1 |

|

2.Repair of rubber pad |

Hebei |

0.75KW 43/1 Gear motor |

1 |

|

Other Explanations |

|||

|

1.bearing |

Ha、Wa、Luo |

Main parts |

|

|

2.electrical appliances |

chint |

All |

|

|

3.Pneumatic diaphragm pump |

Jinchang River in Wuhan |

||

|

4.PLC |

Taiwan |

All |

|

|

5.Encoder |

Zhejiang |

All |

|

|

6.Touch screen |

Kunlun |

All |

|

|

7.Keyless connection ring |

Xianyang |

All |

|

|

8.Overrunning clutch |

Xianyang |

All |

|

|

9.glue roll |

Jizhou |

All |

|

|

10.Metal Screen Roller |

Dalian |

All |

|

|

11.Die-cut rubber pad |

Taiwan |

All |

Note: Customers own air compressors.

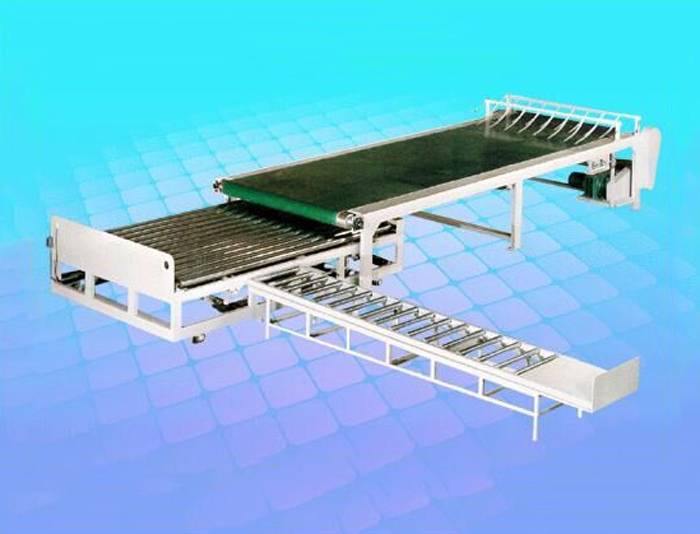

stacking unit

1 paper arm

〖1〗can choose manual or automatic operation.

〖2〗connection arm drive belt, independently adjust the degree of tightness is not restricted by the belt length.

2 bed lifting

〖1〗strong chain drive。

〖2〗stacking height1600㎜。

〖3〗The bed lifting motor is provided with a brake function, and the bed table can be kept in a fixed position and will not slide

〖4〗 install safety protection device, the lifting bed in the control, to ensure the safety of operating personnel.

〖5〗Flat corrugated climbing belt prevents cardboard from sliding。

3 Receiving baffle

〖1〗pressure action paper splicing baffle, piled up to a predetermined height in the cardboard, paper pallets automatically extend, hold the cardboard.

〖2〗 manual adjustment of the rear baffle position.

Product detail pictures:

Related Product Guide:

While using the "Client-Oriented" company philosophy, a demanding high-quality management method, innovative producing products and also a sturdy R&D workforce, we always deliver premium quality merchandise, superb solutions and aggressive selling prices for High definition Flexo Printing Machine - Syk1224 4 Color Printing Slotting Die Cutting With Stacking Machine – Xinguang , The product will supply to all over the world, such as: Sri Lanka, Greece, Paris, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, please do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

Problems can be quickly and effectively resolved, it is worth to be trust and working together.