OEM/ODM Supplier Double Facer Corrugated Machine - Double facer SM-10 – Xinguang

OEM/ODM Supplier Double Facer Corrugated Machine - Double facer SM-10 – Xinguang Detail:

※Structural features:

★Heating plate surface by grinding treatment, hot plate width 600mm, a total of 12 heating plate and cooling 4 m。

★Heating plate with a container board production, in line with national standards for a class pressure vessel, with pressure vessel certificate and inspection certificate。

★Hot plate with intensive gravitational roll structure. Roll adopt pneumatic lifting.

★Heating plate heat transfer pipe temperature control sub-four-segment, with a temperature display.

★on cotton use two-cylinder S type cotton belt with the tensioning device.

★lower belt adopt pneumatic tensioning.

★Drive roller coated with attached wear-resistant rubber ,showed a herringbone structure,With a high, ensure smooth cardboard output。

★Main drive motor for frequency conversion motor,low-speed torque,wide speed range ,reliable, and easy maintenance.

★hot plate internal for partition isolation structure,s-shaped flow of steam,Steam, water separation function significantly improves the utilization of steam。

※Technical parameters:

1、temperature requirement:160—200℃ steam pressure:0.8-1.3Mpa

2、air source pressure:0.6—0.9Mpa

3、Cooling stereotypes length:4m Heating plate quantity:12 pieces

4、hydraulic system pressure:6—8Mpa

※Roller diameter parameters:

1、upper drive rubber roller diameter:¢475mm lower drive rubber roller diameter:¢350mm Wear rubber Outsourcing

2、Former follower with roller diameter:¢176mm back setting belt driven roller diameter:¢176mm

3、Platen roller:¢85mm Setting roller diameter:¢86mm

4、upper belt tension roller diameter:¢155mm upper roll diameter with detuning:¢124mm

5、Lower belt tension roller diameter:¢130mm Entrusted with the roll diameter lower belt:¢130mm

Note: All the roller surface after grinding are hard chrome plated

※Powered motor parameters:

1、Main drive motor power:22KW 380V 50Hz Continuous (S1) working standard

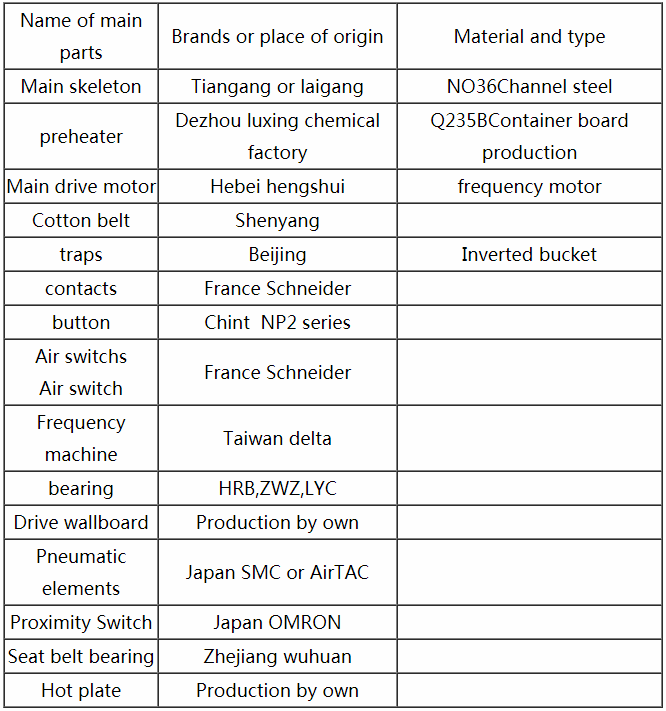

※Mainly purchased parts, raw materials and origin:

Product detail pictures:

Related Product Guide:

We constantly think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body along with the living for OEM/ODM Supplier Double Facer Corrugated Machine - Double facer SM-10 – Xinguang , The product will supply to all over the world, such as: Philadelphia, Atlanta, Sudan, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality items we offer, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We are confident that we'll share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!