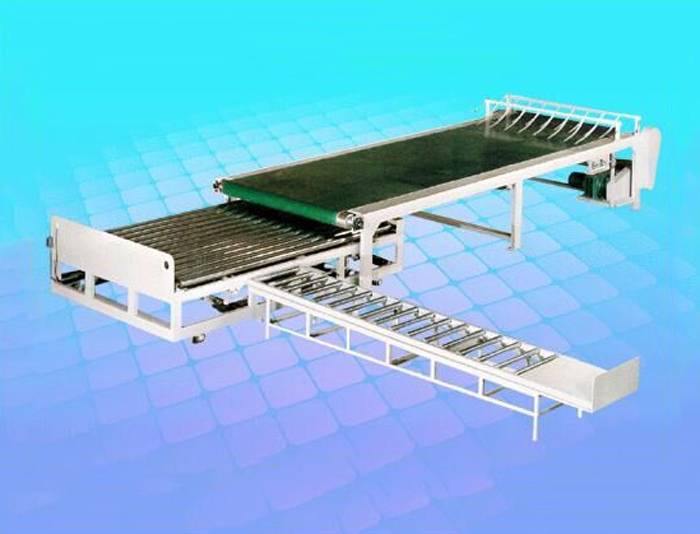

Wholesale Cassette Double Facer Corrugated Machine - Double facer SM-E2 – Xinguang

Wholesale Cassette Double Facer Corrugated Machine - Double facer SM-E2 – Xinguang Detail:

※Structural features:

★surface of hot plate is dealed with grinding, hot plate width600mm,Minister cooling stereotypes 5m。

★Hot plate is made adopt container board, enclosed pressure container certificate and inspection certificate。Internal thermal panels for partition isolation structure,s-shaped flow of steam, Steam, water separation function apparent,improve the using rate of steam。

★upper conveying belt adopt pneumatic correction.

★ piping thermal heating plate temperature control points three sections with temperature display。

★upper conveying belt adopt pneumatic correction.

★Drive roller coated with wear-resistant rubber attached, and with the high output ensure smooth cardboard。

★Gearbox drive unit using an independent structure, gear steel ZG-500 number for materials, the use of oil-immersed gear lubrication。

★Electrical components used internationally renowned brands, the device stable and reliable operation。

★Main drive motor for the motor frequency energy, low-speed torque, wide speed range, reliable, easy maintenance。

★The main backbone of high intensity profiles GB, solid structure, beautiful appearance, suitable for high speed working

※Technical parameters:

1、effective width:2500mm

2、operation direction:left or right(determined in accordance with customer’s factory building)

3、MAX machinery speed:250m/min

4、temperature range:160—200℃

steam pressure:0.8-1.3Mpa

5、air source pressure: 0.6—0.9Mpa

6、quantity of heat plate:20 pieces

※Roller diameter parameters:

1、up drive rubber roller diameter:¢800mm bottom drive rubber roller diameter:¢600mm outsourcing wear rubber

2、Former follower with roller diameter:¢215mm After setting the driven belt rollers diameter :¢215mm

3、pressure belt roller diameter:¢70mm Shaping roller diameter:¢86mm

4、The up belt tension roller diameter:¢155mm up belt detuning roller diameter:¢130mm

5、lower belt tension roller diameter:¢155mm

Note: All the roller surface after grinding are hard chrome plated

※Powered motor parameters:

1、main drive motor power:75KW frequency motor 380V 50Hz continuous(S1)working system

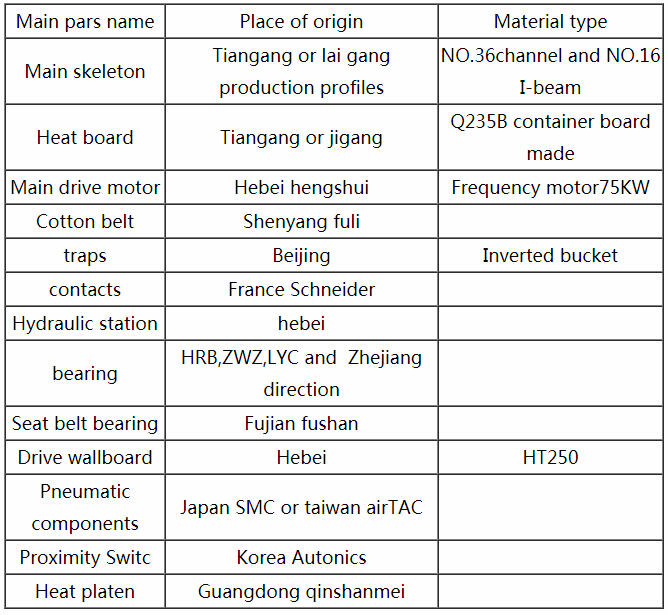

※Mainly purchased parts, raw materials and origin:

Product detail pictures:

Related Product Guide:

With this motto in mind, we've got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Wholesale Cassette Double Facer Corrugated Machine - Double facer SM-E2 – Xinguang , The product will supply to all over the world, such as: Casablanca, Liverpool, Bulgaria, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant experienced knowledge, to develop advanced production equipment and production process , to create the first-call quality goods, reasonable price , high quality of service , quick delivery , to present you create new value .

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!