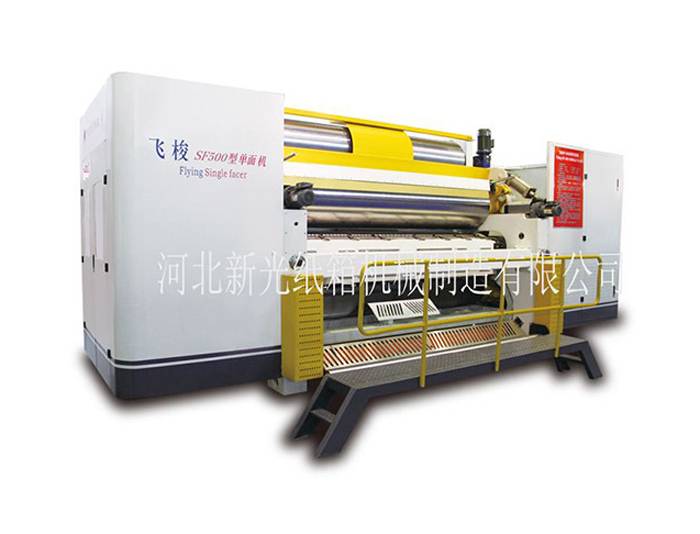

Top Quality Single Facer Forming Machine - Single facer SF-360C1 (405C1) – Xinguang

Top Quality Single Facer Forming Machine - Single facer SF-360C1 (405C1) – Xinguang Detail:

※Structural features:

★adopt suction hood structure,matched high pressure powerful fan. Suction with silence, gas supply and electrical control cabinet to focus on the same operation,away from the host is not less than 1.5m.Operating side closed full cover。

★the base and wallboard cast iron structure, the thickness of wallboard is 200mm。Independent gear box, universal joint transmission structure.

★corrugated roller material adopt 48CrMo alloy steel,diameter of corrugated roller main roller ¢ 360mm,Quenched, CNC grinder grinding, IF quenching, surface finish,surface tungsten carbide dealing, surface hardness above HV1200 degree。Bearing of corrugated roller and pressure roller key parts adopt Timken bearings produce heat.

★pressure roller ¢ 364mm,surface grinding and dealing with chrome,cylinder control moves up and down,No. 45 carbon steel material, quenching (with cushioning devices).

★glue wallboard adopt skateboard-type structure, pneumatic control glue to glue back,diameter of glue roller is ¢240mm, engraved polished surface after a 30-line pit style textured machined chrome plated,After scraping the roller surface polished hard chrome plated

★glue part can remove overall, exchange glue roller quickly and convenient。Electric compartment plastic, electric adjustment amount of glue Digital。

★material of corrugated and pressure is provided by zhongyuan tegang,corrugated roller pressure roller high。A

★corrugated roller and pressure roller adopt air spring pressure device, and working stable 。

★preheat roller adopt seamless steel pipe produced by tiangang¢ 400mm,All metal hose connection

※Technical parameters:

1、effective width:1800mm、2200mm

2、operate direction:left or right(Determined in accordance with the customer’s facility)

3、design speed:200m/min

4、range of temperature:160—180℃

5、air source:0.4—0.9Mpa

6、steam pressure:0.8—1.3Mpa

7、corrugate flute(UVtype or UVVtype)

※Roller diameter parameters:

1、diameter of corrugated roller: ¢360mm

2、diameter of pressure roller: ¢364mm

3、diameter of glue roller: ¢269mm

4、diameter of preheat roller: ¢400mm

※Powered motor parameters:

1、main drive motor:22KW rated voltage:380V 50Hz continuous(S1)working system

2、suction motor:11KW rated voltage:380V 50Hz continuous(S1)working system

3、adjust glue reducer:100W rated voltage:380V 50Hz short (S2)working system

4、adjust glue gap motor:200W*2 rated voltage:380V 50Hz short (S2)working system

5、glue pump motor: 2.2KW rated voltage:380V 50Hz continuous(S1)working system

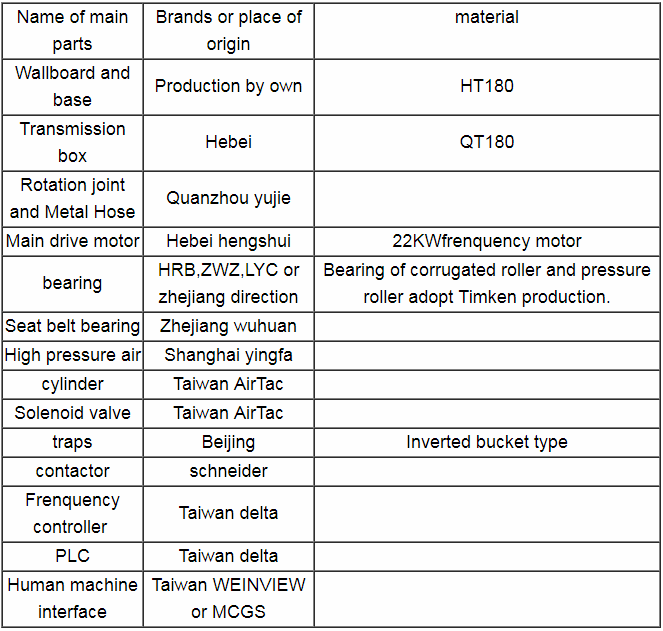

※Mainly purchased parts, raw materials and origi

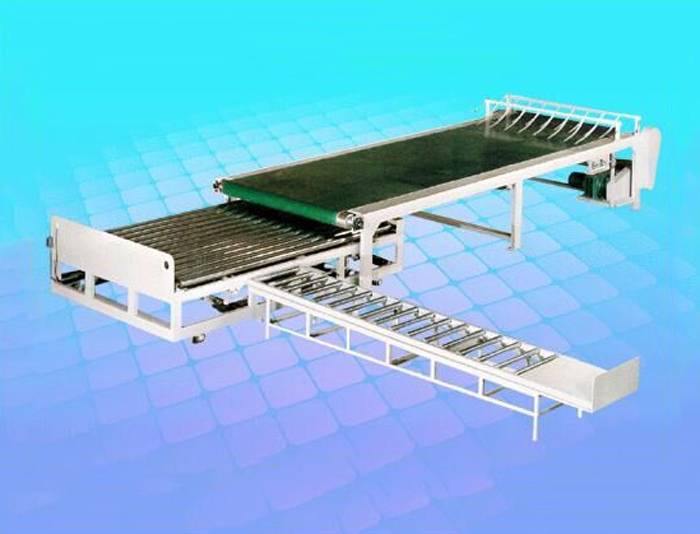

Product detail pictures:

Related Product Guide:

The corporate upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will keep on to serve outdated and new clients from home and abroad whole-heatedly for Top Quality Single Facer Forming Machine - Single facer SF-360C1 (405C1) – Xinguang , The product will supply to all over the world, such as: Israel, Greek, Chile, Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.