OEM Supply Double Layers Double Facer Machine - Double facer SM-F – Xinguang

OEM Supply Double Layers Double Facer Machine - Double facer SM-F – Xinguang Detail:

※Structural features:

★Heating plate surface by grinding treatment,hot plate width600mm.

★Preheat board is made of container board, in accordance with the national standard of pressure container, enclosed the pressure container certificate and inspection certificate.

★Hot plate with intensive gravitational roll structure.Pressure roller with lifting hydraulic structure

★heat pipe of the heating board three section of control temperature, temperature display.

★up cotton belt with double cylinder S cotton belt tensioning device.

★bottom cotton belt with s-shaped correction manually tensioning mechanism, structure simple and practical,under with manual fine-tuning。

★Drive roller coated with attached wear-resistant rubber ,showed a herringbone structure,With a high, ensure smooth cardboard output。

★Main drive motor for frequency conversion motor,low-speed torque,wide speed range ,reliable, and easy maintenance.

★hot plate internal for partition isolation structure,s-shaped flow of steam,Steam, water separation function significantly improves the utilization of steam

※Technical parameters:

1、temperature requirement:160—200℃ steam pressure:0.8-1.3Mpa

2、air source pressure:0.6—0.9Mpa

3、Cooling stereotypes length:4m Heating plate quantity:14 pieces

4、Hydraulic system pressure:6—8Mpa max working width:200m/min

※Roller diameter parameters:

1、upper drive rubber roller diameter:¢440mm lower drive rubber roller diameter: ¢440mm Wear rubber Outsourcing

2、Former follower with roller diameter:¢270mm After setting belt driven roller diameter:¢186mm

3、pressure belt roller diameter:¢70mm Shaping roller diameter:¢86mm

4、The belt tension roller diameter:¢130mm The roll diameter with detuning:¢124mm

5、Under the belt tension roller diameter:¢130mm Entrusted with the roll diameter under the belt:¢130mm

Note: All the roller surface after grinding are hard chrome plated

※Powered motor parameters:

1、Main drive motor power:45KW 380V 50Hz Continuous (S1) working standard

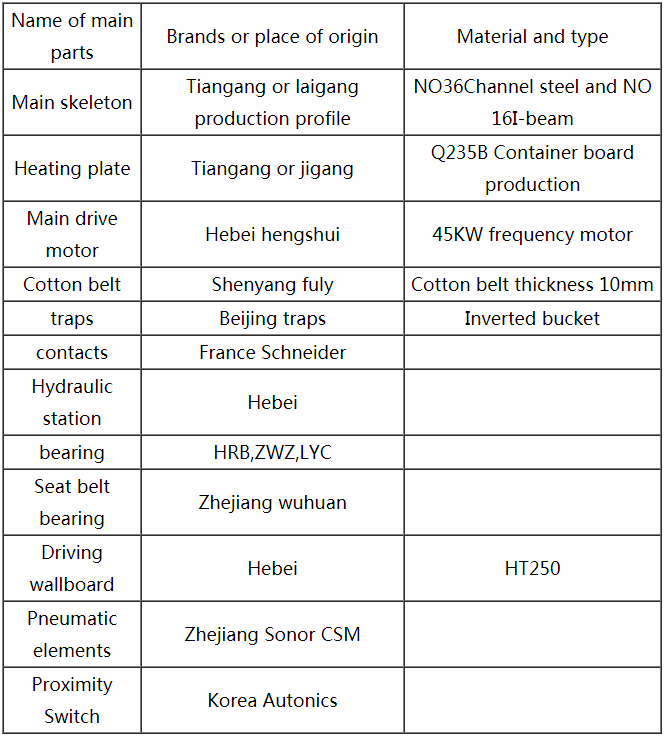

※Mainly purchased parts, raw materials and origin:

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for OEM Supply Double Layers Double Facer Machine - Double facer SM-F – Xinguang , The product will supply to all over the world, such as: Peru, Moldova, Kyrgyzstan, Due to the stability of our items, timely supply and our sincere service, we are able to sell our merchandise not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We will do our best to serve your company, and establish a successful and friendly cooperation with you.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.