OEM Supply Double Layers Double Facer Machine - Double facer SM-F – Xinguang

OEM Supply Double Layers Double Facer Machine - Double facer SM-F – Xinguang Detail:

※Structural features:

★Heating plate surface by grinding treatment,hot plate width600mm.

★Preheat board is made of container board, in accordance with the national standard of pressure container, enclosed the pressure container certificate and inspection certificate.

★Hot plate with intensive gravitational roll structure.Pressure roller with lifting hydraulic structure

★heat pipe of the heating board three section of control temperature, temperature display.

★up cotton belt with double cylinder S cotton belt tensioning device.

★bottom cotton belt with s-shaped correction manually tensioning mechanism, structure simple and practical,under with manual fine-tuning。

★Drive roller coated with attached wear-resistant rubber ,showed a herringbone structure,With a high, ensure smooth cardboard output。

★Main drive motor for frequency conversion motor,low-speed torque,wide speed range ,reliable, and easy maintenance.

★hot plate internal for partition isolation structure,s-shaped flow of steam,Steam, water separation function significantly improves the utilization of steam

※Technical parameters:

1、temperature requirement:160—200℃ steam pressure:0.8-1.3Mpa

2、air source pressure:0.6—0.9Mpa

3、Cooling stereotypes length:4m Heating plate quantity:14 pieces

4、Hydraulic system pressure:6—8Mpa max working width:200m/min

※Roller diameter parameters:

1、upper drive rubber roller diameter:¢440mm lower drive rubber roller diameter: ¢440mm Wear rubber Outsourcing

2、Former follower with roller diameter:¢270mm After setting belt driven roller diameter:¢186mm

3、pressure belt roller diameter:¢70mm Shaping roller diameter:¢86mm

4、The belt tension roller diameter:¢130mm The roll diameter with detuning:¢124mm

5、Under the belt tension roller diameter:¢130mm Entrusted with the roll diameter under the belt:¢130mm

Note: All the roller surface after grinding are hard chrome plated

※Powered motor parameters:

1、Main drive motor power:45KW 380V 50Hz Continuous (S1) working standard

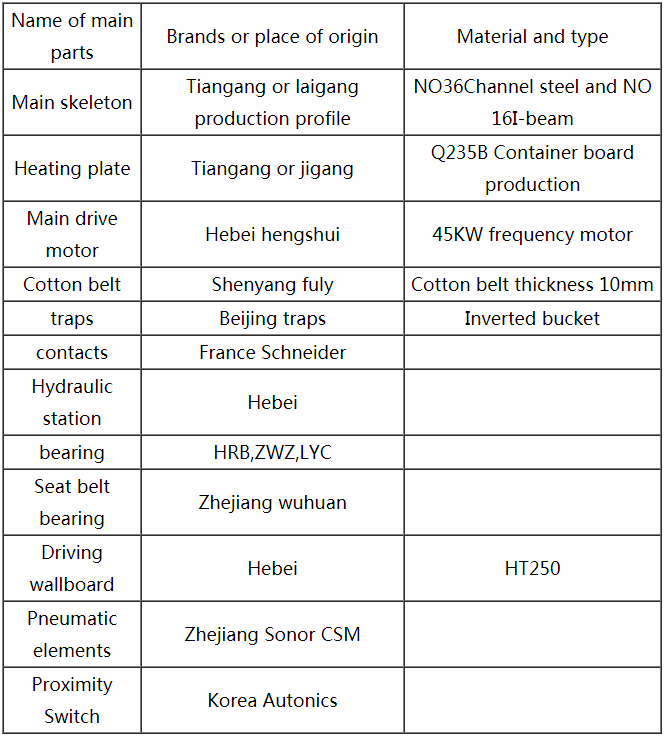

※Mainly purchased parts, raw materials and origin:

Product detail pictures:

Related Product Guide:

We're going to commit ourselves to giving our esteemed customers along with the most enthusiastically considerate providers for OEM Supply Double Layers Double Facer Machine - Double facer SM-F – Xinguang , The product will supply to all over the world, such as: Spain, UK, Doha, Please feel cost-free to send us your specifications and we'll respond to you asap. We've got a professional engineering team to serve for the every single detailed needs. Free samples may be sent for you personally to know far more facts. So that you can meet your desires, please really feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.