OEM manufacturer Double Facer Corrugating Machine - Double facer SM-F – Xinguang

OEM manufacturer Double Facer Corrugating Machine - Double facer SM-F – Xinguang Detail:

※Structural features:

★Heating plate surface by grinding treatment,hot plate width600mm.

★Preheat board is made of container board, in accordance with the national standard of pressure container, enclosed the pressure container certificate and inspection certificate.

★Hot plate with intensive gravitational roll structure.Pressure roller with lifting hydraulic structure

★heat pipe of the heating board three section of control temperature, temperature display.

★up cotton belt with double cylinder S cotton belt tensioning device.

★bottom cotton belt with s-shaped correction manually tensioning mechanism, structure simple and practical,under with manual fine-tuning。

★Drive roller coated with attached wear-resistant rubber ,showed a herringbone structure,With a high, ensure smooth cardboard output。

★Main drive motor for frequency conversion motor,low-speed torque,wide speed range ,reliable, and easy maintenance.

★hot plate internal for partition isolation structure,s-shaped flow of steam,Steam, water separation function significantly improves the utilization of steam

※Technical parameters:

1、temperature requirement:160—200℃ steam pressure:0.8-1.3Mpa

2、air source pressure:0.6—0.9Mpa

3、Cooling stereotypes length:4m Heating plate quantity:14 pieces

4、Hydraulic system pressure:6—8Mpa max working width:200m/min

※Roller diameter parameters:

1、upper drive rubber roller diameter:¢440mm lower drive rubber roller diameter: ¢440mm Wear rubber Outsourcing

2、Former follower with roller diameter:¢270mm After setting belt driven roller diameter:¢186mm

3、pressure belt roller diameter:¢70mm Shaping roller diameter:¢86mm

4、The belt tension roller diameter:¢130mm The roll diameter with detuning:¢124mm

5、Under the belt tension roller diameter:¢130mm Entrusted with the roll diameter under the belt:¢130mm

Note: All the roller surface after grinding are hard chrome plated

※Powered motor parameters:

1、Main drive motor power:45KW 380V 50Hz Continuous (S1) working standard

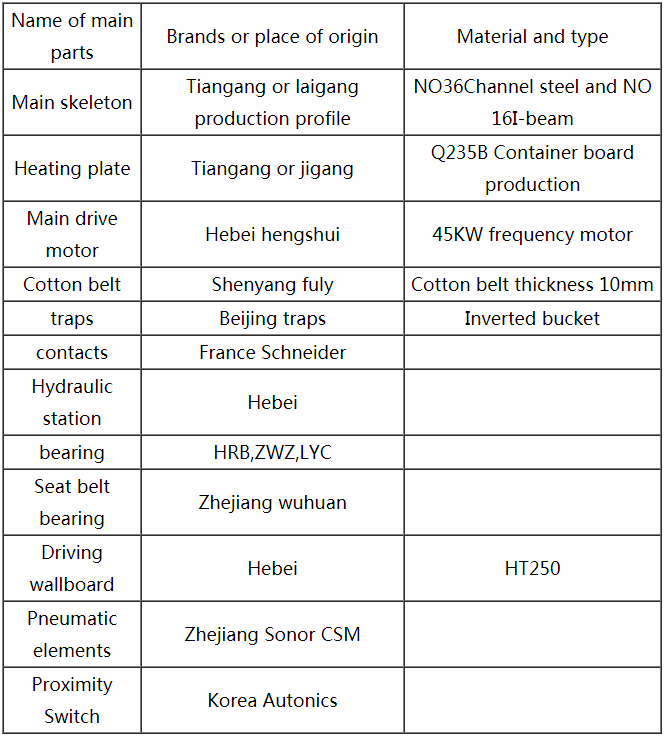

※Mainly purchased parts, raw materials and origin:

Product detail pictures:

Related Product Guide:

Our personnel are always inside the spirit of "continuous improvement and excellence", and together with the outstanding excellent goods, favorable price and good after-sales services, we try to gain every customer's trust for OEM manufacturer Double Facer Corrugating Machine - Double facer SM-F – Xinguang , The product will supply to all over the world, such as: Turkey, Romania, Suriname, We have many years' experience in hair product production, and our strict QC Team and skilled workers will ensure that we give you top hair products with the best hair quality and workmanship. You will get successful business if you choose to cooperate with such a professional manufacturer. Welcome your order cooperation!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.