Hot-selling Double Facer Corrugation Machine - Double facer SM-E2 – Xinguang

Hot-selling Double Facer Corrugation Machine - Double facer SM-E2 – Xinguang Detail:

※Structural features:

★surface of hot plate is dealed with grinding, hot plate width600mm,Minister cooling stereotypes 5m。

★Hot plate is made adopt container board, enclosed pressure container certificate and inspection certificate。Internal thermal panels for partition isolation structure,s-shaped flow of steam, Steam, water separation function apparent,improve the using rate of steam。

★upper conveying belt adopt pneumatic correction.

★ piping thermal heating plate temperature control points three sections with temperature display。

★upper conveying belt adopt pneumatic correction.

★Drive roller coated with wear-resistant rubber attached, and with the high output ensure smooth cardboard。

★Gearbox drive unit using an independent structure, gear steel ZG-500 number for materials, the use of oil-immersed gear lubrication。

★Electrical components used internationally renowned brands, the device stable and reliable operation。

★Main drive motor for the motor frequency energy, low-speed torque, wide speed range, reliable, easy maintenance。

★The main backbone of high intensity profiles GB, solid structure, beautiful appearance, suitable for high speed working

※Technical parameters:

1、effective width:2500mm

2、operation direction:left or right(determined in accordance with customer’s factory building)

3、MAX machinery speed:250m/min

4、temperature range:160—200℃

steam pressure:0.8-1.3Mpa

5、air source pressure: 0.6—0.9Mpa

6、quantity of heat plate:20 pieces

※Roller diameter parameters:

1、up drive rubber roller diameter:¢800mm bottom drive rubber roller diameter:¢600mm outsourcing wear rubber

2、Former follower with roller diameter:¢215mm After setting the driven belt rollers diameter :¢215mm

3、pressure belt roller diameter:¢70mm Shaping roller diameter:¢86mm

4、The up belt tension roller diameter:¢155mm up belt detuning roller diameter:¢130mm

5、lower belt tension roller diameter:¢155mm

Note: All the roller surface after grinding are hard chrome plated

※Powered motor parameters:

1、main drive motor power:75KW frequency motor 380V 50Hz continuous(S1)working system

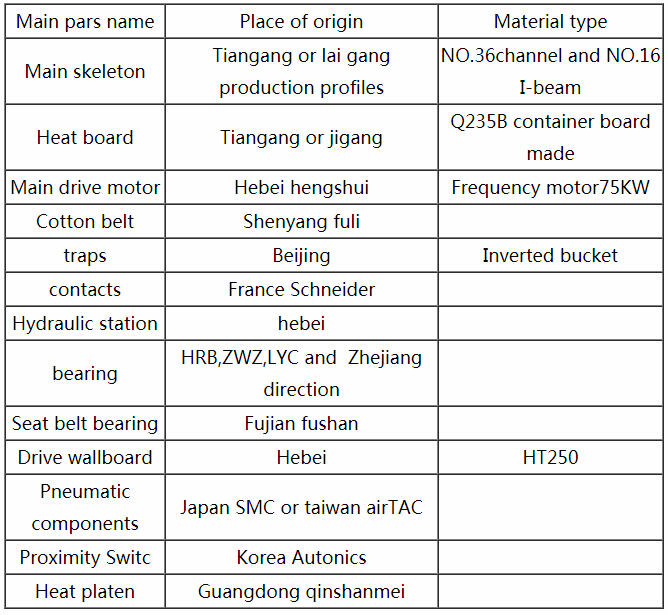

※Mainly purchased parts, raw materials and origin:

Product detail pictures:

Related Product Guide:

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most aggressive costs. So Profi Tools offer you finest benefit of money and we are ready to produce alongside one another with Hot-selling Double Facer Corrugation Machine - Double facer SM-E2 – Xinguang , The product will supply to all over the world, such as: Macedonia, Surabaya, Berlin, Our company has already have pass the ISO standard and we are fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will be the only one can have that products. We hoping that with our good products can bring our customers a great fortune.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!