Hot New Products Die-Cutter Machine - Vertical and horizontal NC-30D – Xinguang

Hot New Products Die-Cutter Machine - Vertical and horizontal NC-30D – Xinguang Detail:

※Structural feature:

★it can store 200 units orders,replace the cutter specifications quickly and accurately,changing orders without stop,And enables networked computers to facilitate production management.

★Knife shaft drive gears are precision forged steel induction hardening, backlash-free transmission, advanced keyless connection, high transmission accuracy。

★Cutting machine adopts inlaid front steel blade knife spiral structure, serrated knife. scissors, shears, shear force, long blade life。

★around feed rollers are used the sun gear platen way, smooth delivery, pressure evenly, easy to crush plate board or cause blockage。

★This model is the braking energy storage (non-dynamic braking), so the energy consumption in the production process, the average electricity consumption is 1/3 of an ordinary NC cutting machine, saving more than 70% power to reach the goal of saving money .

★Precision adjustable no gap gear to ensure precise blade engagement, running balance。

★Using an independent oil pump and filter with two copper distribution in each gear position oil, lubrication and cooling。

★Knife roller: fine quality forged steel material, the balanced, with good stability.

※Technical parameters:

1、MAX working width: 2200mm

2、operation direction:left or right(determined to the customer’s factory)

3、highest machinery speed:200-250m/min

4、Mechanical configuration:computer-control helical cross cutter

5、Minimum cutting length:500mm

6、Maximum cutting length:9999mm

7、Precision of cutting paper:uniform ±1mm,non-uniform±2mm

※Roller diameter parameters:

1、Cross on the knife shaft center distance:¢216mm

2、Before the lower conveying roller diameter ¢156mm

3、After the lower conveying roller diameter:¢156mm

4、The front of the platen roller diameter: ¢70mm

5、The front of the platen roller diameter:¢70mm

Note: After all have been grinding rollers, hard chrome plated at (on except under the knife shaft) dealing.

※Powered motor parameters:

1、main drive motor power:37KW Full AC synchronous servo

2、Before and after feeding motor power:4KW(Frequency Control)

3、Oil pump motor power:0.18KW*2

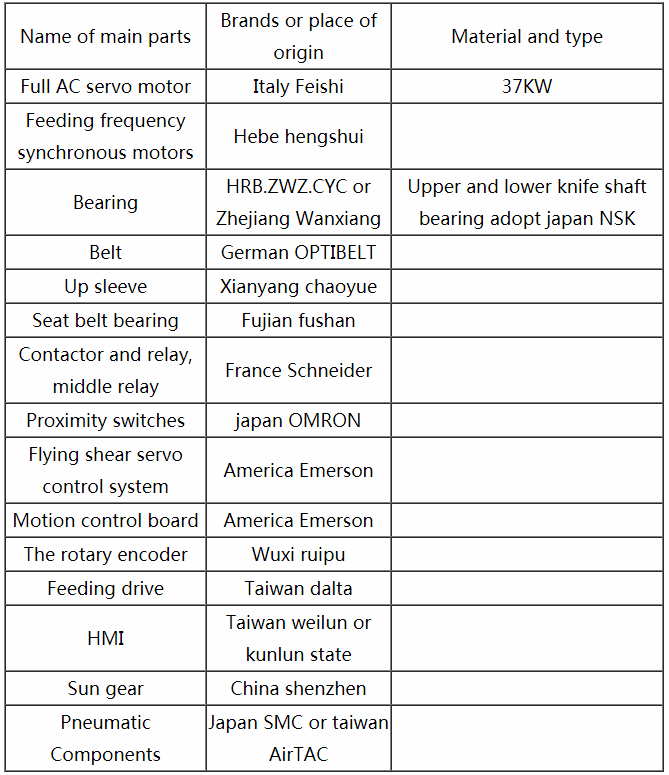

※Mainly purchased parts, raw materials and origin:

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for Hot New Products Die-Cutter Machine - Vertical and horizontal NC-30D – Xinguang , The product will supply to all over the world, such as: Belarus, Romania, Thailand, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we've been committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have now passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.