2021 Latest Design Single Facer Paper Corrugating Machine - Single facer SF-405E – Xinguang

2021 Latest Design Single Facer Paper Corrugating Machine - Single facer SF-405E – Xinguang Detail:

※Structural features:

★design speed:250m/min。

★effective width:1400-2500mm。

★main flute roller:¢405mm(according to flute differ),pressure roller¢495mm,preheat roller¢400mm。

★using negative pressure design, lower heat consumption, helps the core paper to press evenly and close to the surface of corrugated roller, make the corrugate molding better, because the pressure evenly, the top of corrugate can glue uniform and better, make the single corrugated paper have perfect laminating.

★quickly change rollers in 15 minutes, while change corrugated roller with the electric trolley loading,the entire group of corrugating with motor drive,put into the machine,fixed to the machine base,only need a few buttons can complete the replacement quickly and easily.

★corrugated roller adopt 48CRMO high quality alloy steel, dealing with heat,after grinding tungsten carbide surface treatment.

★corrugated roller, pressure roller adopt airbag control system having high stability, having the barometric pressure control buffering effect at the same time.

★Glue volume control with electric adjustment,rubber septum electric device,the glue system can operate independently when the motor stops,prevent glue exhausted。

★the moveable type glue unit is convenient to clean and maintain。

★easy operation control system, touch screen operation interface,Drawing with color display operating status, function selection, fault indication, and parameter settings, etc. can exclude exhibit this machine fully functional, easy to operate, user-friendly.

★built-in pre-conditioner with proportional spraying device, adjustment the core paper temperature and moisture.

★main, vice corrugating and pressure roller bearings are used in high-temperature grease to ensure bearing life running smoothly.

※Technical parameters:

1、working effective:1400-2500mm

2、operation direction:left or right(Determined in accordance with the customer’s facility)

3、design speed:250m/min

4、temperature range:160—200℃

5、air source:0.4—0.9Mpa

6、steam pressure:0.8—1.3Mpa

7、corrugate flute(UV type or UVV type)

※Roller diameter parameters:

1.Main corrugated roller: ¢405mm vice corrugated roller :¢428m

2.pressure roller: ¢495mm glue roller:¢318mm

3.Fixed paste roller: ¢173mm preheat roller:¢400mm

※Powered motor parameters:

1、main frequency drive motor:30KW rated voltage:380V 50Hz Continuous (S1) working standard

2、suction motor:15KW rated voltage:380V 50Hz Continuous (S1) working standard

3、glue reducer linear actuator:30W rated voltage:24V short(S2) working standard

4、glue gap motor:200W*2 rated voltage:380V 50Hz short(S2) working standard

5、glue pump motor: 2.2KW rated voltage:380V 50Hz Continuous (S1) working standard

6、glue frequency motor:3.7KW rated voltage:380V 50Hz Continuous (S1) working standard

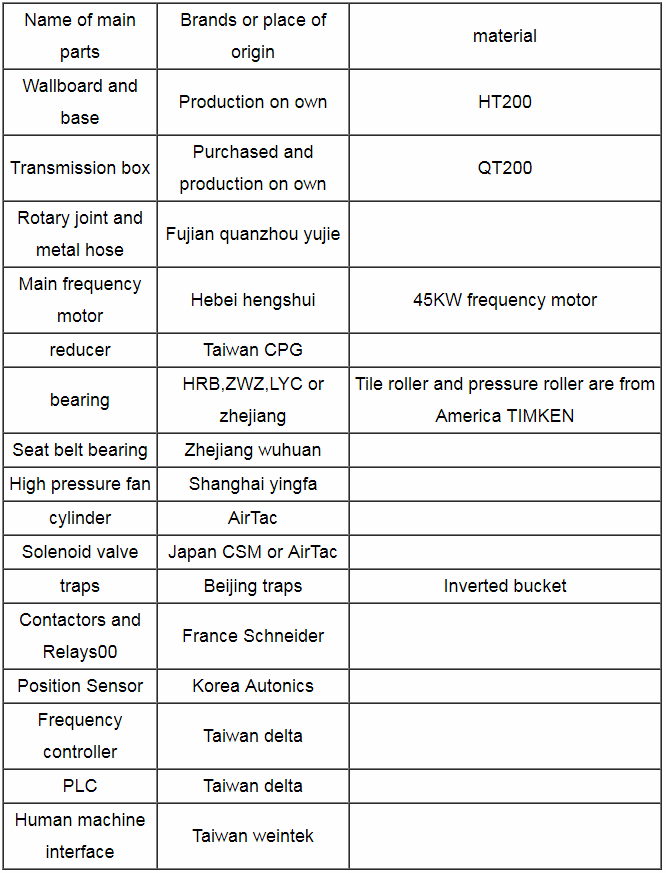

※Mainly purchased parts, raw materials and origin:

Product detail pictures:

Related Product Guide:

Adhering into the basic principle of "quality, assistance, effectiveness and growth", we have attained trusts and praises from domestic and worldwide client for 2021 Latest Design Single Facer Paper Corrugating Machine - Single facer SF-405E – Xinguang , The product will supply to all over the world, such as: Birmingham, Belgium, Irish, Now, with the development of internet, and the trend of internationalization, we have decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.